|

Do you know how to start your Ariens® Sno-Thro®? If you have a non-EFI, or non-electronic fuel injected snow blower, you may need to choke and prime your snow blower engine before starting. Watch how we start a two-stage snow blower engine using the choke and primer in this quick video.

0 Comments

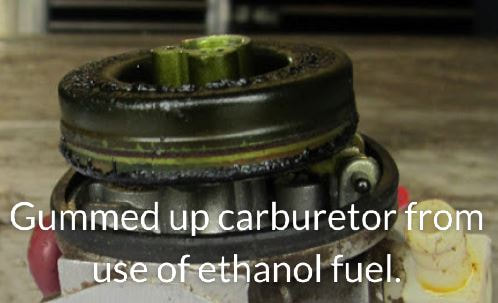

Why is ethanol bad? Ethanol absorbs moisture like a sponge! Ethanol blends have the ability to retain up to 50 times more water than pure gasoline and carry it through your fuel system. After prolonged use, that water corrodes parts like an engine's fuel line and carburetor. Eventually enough rust forms in those narrow passageways to restrict fuel supply causing the engine to not start. The Importance of Pure Gasoline Trips to the pump are a lot different now than they were 20 years ago. With the integration of ethanol into our fuels, we now have to be more careful about which button we push at the pump, especially when filling a fuel tank of small engines such as lawnmowers, snow blowers and chainsaws. Highly recommended fuel tips:

Get drift cutter kit for your snowblower from by calling 613-724-4332 or contact via OttawaSnowBlowers.com

What's the best way to knock down those ice-encrusted drifts at the end of your driveway? With a pair of Ariens® snow blower drift cutters. Ariens Sno-Thro® drift cutters extend higher than your Sno-Thro auger housing to knock down drifts and direct them into your augers. They also cut through tall, hard-packed, ice-encrusted snow piles like those left at the end of your driveway by the snowplow. Watch how to assemble an Ariens® Platinum two-stage Sno-Thro® out of its original crate. Are you assembling your new Ariens® Platinum-series snow blower? Watch this video for a step-by-step breakdown of the installation procedure for the Quick-Turn chute control. For snowblower sale and service in Ottawa contact us How do you change oil in a snow blower? It's easy. Watch our quick video to learn how to replace the engine oil in your Ariens snow blower. Before you start, remember to read the safety instructions in the operator's manual for your unit. If your Ariens® Deluxe, Platinum or Professional series snow blower exhibits erratic tracking, or "pulling" to one side during operation, it can likely be resolved with a simple adjustment. In most cases, this is because the tractor, or frame of the unit is out of alignment with the auger housing, making the Auto-Turn™ technology falsely sense movement and want to turn erratically. Watch our product support team instruct how to make a simple adjustment to help the Auto-Turn feature perform as designed. Before performing service, always read the safety section of your operator's manual. In the Ottawa-Gatineau region, we tend to get more than our fair share of snow falls.

Even if you enjoy winter activities such as skiing or snowboarding, moving snow is not nearly as enjoyable. A good snowblower can allow you to handle snow on your own terms. Be sure to select the right size and model. Keep up with maintenance for ultimate peace of mind. Snowblower buying tips: 1. Search online, read reviews and reach out to a reputable local servicing dealer for professional advice. 2. Respect your budget but also get a quality snowblower with enough power, clearing width, and features to handle your needs and regional climate. 3.Best to get it professionally assembled and tested before use. Ask about maintenance requirements and service plan for ultimate peace of mind. This article was published in YARMAND Magazine Fall/Winter 2020. Learn more https://issuu.com/yarmand If your snow blower augers stop moving your snow blower feels like it's pushing snow, or your snow blower isn't throwing as much snow, you may have broken a shear bolt. Your snow blower shear bolt secures your augers to the auger shaft, but if an obstruction jams and stops your augers, the shear bolt breaks, or shears, to protect your auger gearcase. This video shows how to replace a broken snow blower auger shear bolt on an Ariens® Sno-Thro®. Snowblower Parts Online Ordering. Get it shipped anywhere in Canada. Do you know the right way to store your snow blower for the summer? If you didn't know, it requires more than just putting it in the shed for a few months. Your snow blower needs your attention now so it's ready for next year's first snow storm. Watch as we show you how to stabilize your snow blower gasoline and lubricate your snow blower before putting it away for the season. Need service or parts? Find them at your local trusted source: www.OttawaSnowBlowers.com Now that winter is upon us, cleaning snow can be a daunting task for most residence. Especially in more recent winters our region has received it’s fair share of snowfall and storms. It’s important to be prepared with the right tools to weather any storm safely.

Safety while using a snowblower:

Is it OK to blend fuels from season to season? What's the difference between summer and winter fuel?

Published 12/03/2012 11:47 AM | Updated 06/14/2013 12:12 PM Depending on your state's regulations, there could be up to a 30+ blend of fuel each year depending on the outside temperature. Purchase fresh fuel for your lawn and snow equipment in smaller quantities and just prior to using it for the season. It is not recommended that fuel be used from the prior season. (This applies to all fuels with 10% ethanol or less.) Winter fuel is blended to have a higher amount of vapor coming off the fuel. This helps winter equipment start in cold temperatures. However, this also causes the fuel to age quicker and if the fuel is not treated with a fuel stabilizer it will start to break down after (approximately) 30 days, causing the carburetor to plug. (This is a common scenario between winter seasons when untreated fuel is left in the fuel system.) Note: Winter fuel will breakdown at an accelerated rate, if not treated, when the temperature starts to rise in the spring of the year. So, winter fuel will work in summer engines because it is very highly volatile due to the high amount vapor coming off the fuel. Summer blended fuel will give off far less vapors and is designed for warm weather equipment use. Summer fuel has a longer life span with less need for a stabilizer. Summer fuel doesn't work well in winter equipment when trying to start an engine in 30 degree weather. Note: Fuel stabilizer is also recommended for summer fuel, due to its detergent additives that help to keep the fuel system clean at all times. Source: http://ariens.custhelp.com/app/answers/detail/a_id/434/related/1 Why do I need to pay attention to the fuel? If you buy your gas at a gas station in North America then more than likely what you are buying contains corn-based ethanol.

Because today’s gasoline contains ethanol and alcohol, it absorbs water if exposed to air. In many cases the operator is unaware that their gasoline has become contaminated with water and unintentionally pours it into their unit. This is because your fuel mixture will separate into layers if it contains a high enough percentage of water. If you don’t shake your mixture, you may unintentionally pour a damaging concentration of water into your unit. Always vigorously shake the fuel mixture immediately before pouring. Always stabilize your fuel to minimize this problem. Ethanol fuel or ethyl alcohol is an alcohol additive that is commonly used in nearly all gasoline. It is derived from renewable resources such as corn, sugarcane and wheat. We recommend using at least 89- octane which is the mid-grade between medium and premium gasoline. Fuel that is labelled E-15, E-20, E-85 and Diesel fuel are not acceptable fuels and will cause significant damage to outdoor power equipment. Possible Symptoms related to fuel: > engine is difficult to start > engine starts but doesn't run smooth > gas is leaking from carburetor > Cracked/damaged fuel line If any of these symptoms apply to your equipment, it may require a carburetor overhaul. After carburetor has been overhauled, follow the following preventative steps to avoid the problem in the future. PREVENTATIVE ACTION STEPS RECOMMENDED: 1. DO NOT use any old gas sitting in your fuel container for more than 30 days. 2. Get some premium (at least 89 octane) fresh fuel. Only get enough for the season. 3. Add fuel stabilizer into the fuel container as soon as you get the gas. (use stabilizer with advanced formula that can treat ethanol blend) 4. Storage procedure: a. Fill up gas tank to the top b. Add some more fuel stabilizer to the gas tank. c. Run machine for 2-3 minutes to circulate fuel. Store machine safely. Related Post: http://www.ottawachainsaws.com/1/post/2012/08/what-type-of-fuel-to-use-avoid-gas-with-ethanol.html For more information contact the experts: www.OttawaSnowBlowers.com Ph: 613-724-4332 You may find that during a snowstorm the snowblower auger (s) stops turning all of a sudden.

This may be due to broken auger shear bolts. Luckily it's a simple and inexpensive fix.The purpose of auger pins or bolts are to act as a safety mechanism to prevent any severe damage due to overload. So, if you were to go thru heavy snow or catch something in the auger, the bolts 'shear' to prevent any damage to the auger differential gears. When you break a shear pin, make sure to replace it with the proper bolts or pin made for your machine. Don't use any ordinary bolt or nail because they may not break under heavy load and can cause major damage. It's always a good idea to keep couple of spares in case you need them . Other causes of snowblower not throwing snow: - Loose/worn Auger belt - Worn impeller bearing - Broken impeller bolts - Worn differential gears |

Links to our other sites:* Prices subject to change without notice. Delivery limited to local Ottawa area.

|

|

© 2001-2024 Yarmand Tech Ltd. www.Yarmand.ca Powered by: ClientsViews.com

RSS Feed

RSS Feed